Trace your olive oil back to its original tree!

We aim to provide total transparency to our customers, so we developed a technology that enables you to follow all the stages of production.

Classic Sicilian Taste

Classic Sicilian fruity Extra Virgin Olive Oil from small producers and non-intensive agriculture. This Signature Blend is inspired by the traditional aromas and flavours of Sicily. CUIMANI Extra Virgin Olive Oil is made with a love for nature, and it is complemented by an attentive, verified process respecting traditions.

Cultivars present in Cuimani Classico

- 60% Biancolilla

- 40% Nocellara del Belice

Characteristics of the Cultivars

Biancolilla

- Taste profile: light, slightly spicy and fruity, sometimes with hints of tomato, artichoke, almond, and fresh grass.

- Fruit: a small fruit, which reaches a maximum of four grams in weight and assumes a slightly asymmetrical, elliptical shape.

- Curiosity: it is a Sicilian autochthonous cultivar and owes its name to the fact that during the ripening phase, the fruits change from the typical green color of the unripe fruit to a shade of red tending to purple.

Nocellara del Belice

- Taste profile: medium fruity with notes of almond, green tomato, cut grass, and artichoke. The taste is bitter, slightly spicy, and with a hint of sweetness.

- Fruit: it has a spherical and symmetrical shape and a very large size, with a weight between four and eight grams.

- Curiosity: it represents a very valuable cultivar and is, among the Sicilian autochthonous varieties, probably one of the most esteemed ever, so much that in 1998 it obtained the DOP certification (protected designation of origin).

Taste Profile and Food Pairing

You can use Cuimani Classico both to complement the flavours of your ingredients by blending it in the cooking process or to contrast the flavours of your ingredients by highlighting the olive oil fruitiness, spiciness, and bitterness.

Sensory profile: the high percentage of Biancolilla is manifested in the characteristic flavours of central Sicily. Nocellara del Belice brings the spiciness and bitterness into the flavour mix to make Cuimani Classico a well balanced Extra Virgin Olive Oil.

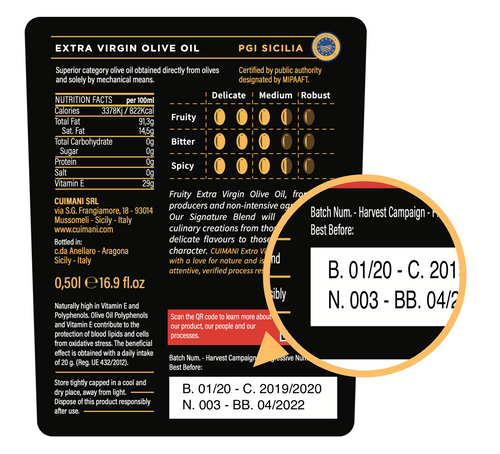

Food pairing recommendation: thanks to its perfect balance, Cuimani Classico is ideal for any type of food. We especially recommend it pure on dishes that can benefit from the fruitiness of the product, like crudités and salads, as well as an ingredient for dishes like baked goods, meat or vegetables. The chart on the left provides you with more information about Cuimani Classico and food pairing.

The Olive Groove

| Altitude | Between 500 and 800 meters above sea level |

|---|---|

| Age of the trees | Between 40 and 150 years old |

| Soil type | Clayey and sandy |

| Number of trees | Max 277 trees / hectare |

| Harvesting | From October to early November |

From farming to bottling

1) FARMING

Our cultivars follow a non-intensive set-up with a distance of at least seven meters between each tree. The abundant spaces guarantee a healthy and natural growth of the plant and a complete exposure to sunlight for optimal vegetation. Among the most important phases of the farming we can mention: Pruning: pruning takes place in the month of January during the vegetative rest and represents an important support for the plant to balance the vegetative growth with the fruiting. Our pruning follows the polyconic or annual light pot cutting technique, which helps the plant to absorb much more light, thus being reinvigorated.

Fertilisation: the biological fertilisation of the soil is carried out in the months of February and March, with the aim of providing the plant with the necessary nutrients to strengthen itself in view of the flowering and fruit production. It is supplemented by foliar fertilisation to improve the natural defenses against parasites such as the olive fly.

2) HARVESTING

Cuimani olives are harvested between October and early November, depending on the variety and altitude on which the ripening stage relies on.

Methodology: t the harvest takes place mostly manually with the help of olive pickers, avoiding subjecting the olives to stress.

Storage: once collected, the fruits are placed in very large perforated boxes called bins. Our producers only use wide-meshed bins, which favor the passage of air and thus prevent the olive fermentation. The fermentation process reduces the quality of the olives, resulting in less nutrients and higher levels of peroxide in the final product.

Transportation to the oil mill:: after the harvest is complete and the olives have been placed in the bins, they are transported to one of our certified partner oil mills with the IGP brand for milling. In order to ensure high levels of freshness, it is important that the olives are milled within a few hours after the harvesting. Otherwise, depending on the climate and environmental conditions (e.g. temperature, exposure to the sun), the high quality fruit would deteriorate, losing part of its nutrients. To guarantee very little time between harvesting and milling, our farmers go to the closest certified oil mills, mostly on appointment to ensure the fastest milling at the arrival.

3) MILLING

Once the olives have been harvested, they are ready for milling in one of our partner's olive oil mills under the PGI Sicilia standards.

Milling is one of the most crucial phases of the production of very high quality olive oil: a milling temperature above 27 degrees, a malfunction in the kneading phase, or a fast extraction can ruin the final product and all the work done in the field to select the best fruits.

For this reason, we rely exclusively on modern machinery and Olive Oil Masters (Mastro Oleario in Italian), who have been carrying out this craftsmanship for generations.

Our Olive Oil Masters, with their knowledge, their manual skills, and the continuous monitoring of the milling process in person, manage to guarantee high production standards in this very delicate phase. Our olive oil is always cold extracted.

4) QUALITY CONTROL

Cuimani carefully supervises every single step of the production chain, ensuring high quality standards. Our quality checks take place mainly in four phases:

- Selection of the olives: our first quality control takes place directly on the field, where we select only the best fruits thanks to the manual harvesting. In this way we are able to sort out lower quality olives before they even reach the oil mill.

- Organoleptic analysis at the mill: as soon as we have milled the olives, we immediately carry out the organoleptic analysis of the produced oil. Thanks to a technological device, the Oxitester, we are able to measure the levels of acidity, polyphenols and peroxides in the oil in real time. Among the many olive oils, we select only the one with the highest quality and the best results from the Oxitester.

- Post-milling sensory analysis: after selecting the olive oils with the best organoleptic properties, they are subjected to a sensory evaluation by expert tasters, the equivalent of sommeliers in the wine sector. With their help, we select the olive oils with the best olfactory and gustatory profiles, such as oils with intense fruitiness and the right balance between bitter and spicy.

- Organoleptic and multi-residual analysis in the laboratory: after selecting and creating the best blends, we send our samples to third-party laboratories accredited by the Ministry of Health for further verification of the sensory and organoleptic parameters of our olive oil. This step is very important to ensure the veracity of a high quality olive oil that is free of pesticides and defects, with a balanced sensory profile.

5) STORAGE

Once milled, the fresh olive oil is stored in air-tight silos with a nitrogen system in a controlled temperature environment. In this way we are able to protect our oil from air, light, and temperature changes, which represent the main enemies of the oil since they favor the oxidation of nutrients and accelerate their deterioration irreversibly. Each silo contains a unique identification code, through which it is possible to trace the complete path of the olive oil.

6) BOTTLING

Distinguishing features: Cuimani Extra Virgin Olive Oil is bottled in dark-colored containers for a better protection from light, for which we use sustainable and highly recyclable materials such as glass. Bottling takes place in small batches just before the olive oil is picked up by the carrier in order to guarantee a fresh product all year round.

Quality control: Cuimani produces its olive oil under the standards of the Protected Geographical Indication (PGI Sicilia), which is subjected to further quality controls even after bottling. At each bottling our samples are delivered to IRVOS, the body that regulates the PGI Sicilia olive oil production and verifies that the olive oil on the label exactly matches its real content. From the sensorial profile, to the organoleptic properties, to the origin of the product.

Unique Sensory Experience

Fruity Extra Virgin Olive Oil from small producers and non-intensive agriculture. This Signature Blend will enhance your culinary creations, from those with the most delicate flavours to those with a stronger character. CUIMANI Extra Virgin Olive Oil is made with a love for nature, and it is complemented by an attentive, verified process respecting traditions.

Cultivars present in Cuimani Chef

- 50% Nocellara del Belice

- 20% Biancolilla

- 30% Ogliarola Messinese

Characteristics of the Cultivars

Nocellara del Belice

- Taste profile: medium fruity with notes of almond, green tomato, cut grass, and artichoke. The taste is bitter, slightly spicy, and with a hint of sweetness.

- Fruit: it has a spherical and symmetrical shape and a very large size, with a weight between four and eight grams.

- Curiosity: it represents a very valuable cultivar and is, among the Sicilian autochthonous varieties, probably one of the most esteemed ever, so much that in 1998 it obtained the DOP certification (protected designation of origin).

Biancolilla

- Taste profile: light, slightly spicy and fruity, sometimes with hints of tomato, artichoke, almond, and fresh grass.

- Fruit: a small fruit, which reaches a maximum of four grams in weight and assumes a slightly asymmetrical, elliptical shape.

- Curiosity: it is a Sicilian autochthonous cultivar and owes its name to the fact that during the ripening phase, the fruits change from the typical green color of the unripe fruit to a shade of red tending to purple.

Ogliarola Messinese

- Taste profile: balanced in spiciness and bitterness, sometimes with hints of freshly cut grass leaf, almond, tomato and artichoke.

- Fruit: a large fruit, which can grow above eight grams in weight and assumes a slightly asymmetrical, elliptical shape.

- Curiosity: it is a Sicilian autochthonous cultivar and the fruits are also consumed as the table olives.

Taste Profile and Food Pairing

You can use Cuimani Chef both to complement the flavours of your ingredients by blending it in the cooking process or to contrast the flavours of your ingredients by highlighting the olive oil fruitiness, spiciness, and bitterness.

Sensory profile: the high percentage of Nocellara del Belice gives Cuimani Chef a rich and fruity profile.

The spiciness of Nocellara del Belice is complemented by the sweet taste of the Biancolilla, while the Ogliarola Messinese adds a little bitterness for a perfect balance.The end result is an olive oil developed for those looking for robust flavours and a unique sensorial experience.

Food pairing: thanks to its full-bodied and fruity profile, Cuimani Chef is going to enhance the taste of every dish. We especially recommend it for foods with strong flavours, such as aged cheeses and red meats, as well as soups and stews. The chart on the left provides you with more information about Cuimani Chef and food pairing.

The Olive Groove

| Altitude | Between 500 and 800 meters above sea level |

|---|---|

| Age of the trees | Between 40 and 150 years old |

| Soil type | Clayey and sandy |

| Number of trees | Max 277 trees / hectare |

| Harvesting | From October to early November |

From farming to bottling

1) FARMING

Our cultivars follow a non-intensive set-up with a distance of at least seven meters between each tree. The abundant spaces guarantee a healthy and natural growth of the plant and a complete exposure to sunlight for optimal vegetation. Among the most important phases of the farming we can mention: Pruning: pruning takes place in the month of January during the vegetative rest and represents an important support for the plant to balance the vegetative growth with the fruiting. Our pruning follows the polyconic or annual light pot cutting technique, which helps the plant to absorb much more light, thus being reinvigorated.

Fertilisation: the biological fertilisation of the soil is carried out in the months of February and March, with the aim of providing the plant with the necessary nutrients to strengthen itself in view of the flowering and fruit production. It is supplemented by foliar fertilisation to improve the natural defenses against parasites such as the olive fly.

2) HARVESTING

Cuimani olives are harvested between October and early November, depending on the variety and altitude on which the ripening stage relies on.

Methodology: t the harvest takes place mostly manually with the help of olive pickers, avoiding subjecting the olives to stress.

Storage: once collected, the fruits are placed in very large perforated boxes called bins. Our producers only use wide-meshed bins, which favor the passage of air and thus prevent the olive fermentation. The fermentation process reduces the quality of the olives, resulting in less nutrients and higher levels of peroxide in the final product.

Transportation to the oil mill:: after the harvest is complete and the olives have been placed in the bins, they are transported to one of our certified partner oil mills with the IGP brand for milling. In order to ensure high levels of freshness, it is important that the olives are milled within a few hours after the harvesting. Otherwise, depending on the climate and environmental conditions (e.g. temperature, exposure to the sun), the high quality fruit would deteriorate, losing part of its nutrients. To guarantee very little time between harvesting and milling, our farmers go to the closest certified oil mills, mostly on appointment to ensure the fastest milling at the arrival.

3) MILLING

Once the olives have been harvested, they are ready for milling in one of our partner's olive oil mills under the PGI Sicilia standards.

Milling is one of the most crucial phases of the production of very high quality olive oil: a milling temperature above 27 degrees, a malfunction in the kneading phase, or a fast extraction can ruin the final product and all the work done in the field to select the best fruits.

For this reason, we rely exclusively on modern machinery and Olive Oil Masters (Mastro Oleario in Italian), who have been carrying out this craftsmanship for generations.

Our Olive Oil Masters, with their knowledge, their manual skills, and the continuous monitoring of the milling process in person, manage to guarantee high production standards in this very delicate phase. Our olive oil is always cold extracted.

4) QUALITY CONTROL

Cuimani carefully supervises every single step of the production chain, ensuring high quality standards. Our quality checks take place mainly in four phases:

- Selection of the olives: our first quality control takes place directly on the field, where we select only the best fruits thanks to the manual harvesting. In this way we are able to sort out lower quality olives before they even reach the oil mill.

- Organoleptic analysis at the mill: as soon as we have milled the olives, we immediately carry out the organoleptic analysis of the produced oil. Thanks to a technological device, the Oxitester, we are able to measure the levels of acidity, polyphenols and peroxides in the oil in real time. Among the many olive oils, we select only the one with the highest quality and the best results from the Oxitester.

- Post-milling sensory analysis: after selecting the olive oils with the best organoleptic properties, they are subjected to a sensory evaluation by expert tasters, the equivalent of sommeliers in the wine sector. With their help, we select the olive oils with the best olfactory and gustatory profiles, such as oils with intense fruitiness and the right balance between bitter and spicy.

- Organoleptic and multi-residual analysis in the laboratory: after selecting and creating the best blends, we send our samples to third-party laboratories accredited by the Ministry of Health for further verification of the sensory and organoleptic parameters of our olive oil. This step is very important to ensure the veracity of a high quality olive oil that is free of pesticides and defects, with a balanced sensory profile.

5) STORAGE

Once milled, the fresh olive oil is stored in air-tight silos with a nitrogen system in a controlled temperature environment. In this way we are able to protect our oil from air, light, and temperature changes, which represent the main enemies of the oil since they favor the oxidation of nutrients and accelerate their deterioration irreversibly. Each silo contains a unique identification code, through which it is possible to trace the complete path of the olive oil.

6) BOTTLING

Distinguishing features: Cuimani Extra Virgin Olive Oil is bottled in dark-colored containers for a better protection from light, for which we use sustainable and highly recyclable materials such as glass. Bottling takes place in small batches just before the olive oil is picked up by the carrier in order to guarantee a fresh product all year round.

Quality control: Cuimani produces its olive oil under the standards of the Protected Geographical Indication (PGI Sicilia), which is subjected to further quality controls even after bottling. At each bottling our samples are delivered to IRVOS, the body that regulates the PGI Sicilia olive oil production and verifies that the olive oil on the label exactly matches its real content. From the sensorial profile, to the organoleptic properties, to the origin of the product.

Exceptionally high in antioxidant

Smooth and fruity Extra Virgin Olive Oil from small producers and non-intensive agriculture. This Signature Blend is for those who pay special attention to leading a healthy lifestyle. CUIMANI Extra Virgin Olive Oil is made with a love for nature, and it is complemented by an attentive, verified process respecting traditions.

Cultivars present in Cuimani Vita

- 60% Cerasuola

- 20% Nocellara Del Belice

- 20% Biancolilla

Characteristics of the Cultivars

Cerasuola

- Taste profile: medium fruity oil, medium bitter with hints of freshly cut grass, artichoke, and tomato.

- Fruit: large fruit, which weighs between four and seven grams and manifests numerous large-sized lenticels.

- Curiosity: the olives are only used for oil production. To produce the fruits, Cerasuola trees need to be pollinated by other cultivars, of which generally Nocellara del Belice, Biancolilla, and Giarraffa are preferred.

Nocellara del Belice

- Taste profile: medium fruity with notes of almond, green tomato, cut grass, and artichoke. The taste is bitter, slightly spicy, and with a hint of sweetness.

- Fruit: it has a spherical and symmetrical shape and a very large size, with a weight between four and eight grams.

- Curiosity: it represents a very valuable cultivar and is, among the Sicilian autochthonous varieties, probably one of the most esteemed ever, so much that in 1998 it obtained the DOP certification (protected designation of origin).

Biancolilla

- Taste profile: light, slightly spicy and fruity, sometimes with hints of tomato, artichoke, almond, and fresh grass.

- Fruit: a small fruit, which reaches a maximum of four grams in weight and assumes a slightly asymmetrical, elliptical shape.

- Curiosity: it is a Sicilian autochthonous cultivar and owes its name to the fact that during the ripening phase, the fruits change from the typical green color of the unripe fruit to a shade of red tending to purple.

Taste Profile and Food Pairing

You can use Cuimani Vita both to complement the flavours of your ingredients by blending it in the cooking process or to contrast the flavours of your ingredients by highlighting the olive oil fruitiness, spiciness, and bitterness.

Sensory profile: this olive oil clearly shows the vegetable hints of artichoke, green almond and wild rocket. The body is very silky with a gentle taste, well structured and bitter, with a pronounced and pleasantly persistent spiciness. The end result is a perfectly developed product for those looking for a mild olive oil with a silky character.

Food pairing: thanks to its velvety and delicate profile, Cuimani Vita is perfect for a wide variety of combinations. We recommend it especially on white meats, soups, and vegetables. Because of its smooth character to the palate, Cuimani Vita is ideal as a raw condiment on salads and crudités. It is also especially recommended for any food with a medium-light taste and as a substitute for butter for baking a vast variety of goods.

The Olive Groove

| Altitude | Between 500 and 800 meters above sea level |

|---|---|

| Age of the trees | Between 40 and 150 years old |

| Soil type | Clayey and sandy |

| Number of trees | Max 277 trees / hectare |

| Harvesting | From October to early November |

From farming to bottling

1) FARMING

Our cultivars follow a non-intensive set-up with a distance of at least seven meters between each tree. The abundant spaces guarantee a healthy and natural growth of the plant and a complete exposure to sunlight for optimal vegetation. Among the most important phases of the farming we can mention: Pruning: pruning takes place in the month of January during the vegetative rest and represents an important support for the plant to balance the vegetative growth with the fruiting. Our pruning follows the polyconic or annual light pot cutting technique, which helps the plant to absorb much more light, thus being reinvigorated.

Fertilisation: the biological fertilisation of the soil is carried out in the months of February and March, with the aim of providing the plant with the necessary nutrients to strengthen itself in view of the flowering and fruit production. It is supplemented by foliar fertilisation to improve the natural defenses against parasites such as the olive fly.

2) HARVESTING

Cuimani olives are harvested between October and early November, depending on the variety and altitude on which the ripening stage relies on.

Methodology: t the harvest takes place mostly manually with the help of olive pickers, avoiding subjecting the olives to stress.

Storage: once collected, the fruits are placed in very large perforated boxes called bins. Our producers only use wide-meshed bins, which favor the passage of air and thus prevent the olive fermentation. The fermentation process reduces the quality of the olives, resulting in less nutrients and higher levels of peroxide in the final product.

Transportation to the oil mill:: after the harvest is complete and the olives have been placed in the bins, they are transported to one of our certified partner oil mills with the IGP brand for milling. In order to ensure high levels of freshness, it is important that the olives are milled within a few hours after the harvesting. Otherwise, depending on the climate and environmental conditions (e.g. temperature, exposure to the sun), the high quality fruit would deteriorate, losing part of its nutrients. To guarantee very little time between harvesting and milling, our farmers go to the closest certified oil mills, mostly on appointment to ensure the fastest milling at the arrival.

3) MILLING

Once the olives have been harvested, they are ready for milling in one of our partner's olive oil mills under the PGI Sicilia standards.

Milling is one of the most crucial phases of the production of very high quality olive oil: a milling temperature above 27 degrees, a malfunction in the kneading phase, or a fast extraction can ruin the final product and all the work done in the field to select the best fruits.

For this reason, we rely exclusively on modern machinery and Olive Oil Masters (Mastro Oleario in Italian), who have been carrying out this craftsmanship for generations.

Our Olive Oil Masters, with their knowledge, their manual skills, and the continuous monitoring of the milling process in person, manage to guarantee high production standards in this very delicate phase. Our olive oil is always cold extracted.

4) QUALITY CONTROL

Cuimani carefully supervises every single step of the production chain, ensuring high quality standards. Our quality checks take place mainly in four phases:

- Selection of the olives: our first quality control takes place directly on the field, where we select only the best fruits thanks to the manual harvesting. In this way we are able to sort out lower quality olives before they even reach the oil mill.

- Organoleptic analysis at the mill: as soon as we have milled the olives, we immediately carry out the organoleptic analysis of the produced oil. Thanks to a technological device, the Oxitester, we are able to measure the levels of acidity, polyphenols and peroxides in the oil in real time. Among the many olive oils, we select only the one with the highest quality and the best results from the Oxitester.

- Post-milling sensory analysis: after selecting the olive oils with the best organoleptic properties, they are subjected to a sensory evaluation by expert tasters, the equivalent of sommeliers in the wine sector. With their help, we select the olive oils with the best olfactory and gustatory profiles, such as oils with intense fruitiness and the right balance between bitter and spicy.

- Organoleptic and multi-residual analysis in the laboratory: after selecting and creating the best blends, we send our samples to third-party laboratories accredited by the Ministry of Health for further verification of the sensory and organoleptic parameters of our olive oil. This step is very important to ensure the veracity of a high quality olive oil that is free of pesticides and defects, with a balanced sensory profile.

5) STORAGE

Once milled, the fresh olive oil is stored in air-tight silos with a nitrogen system in a controlled temperature environment. In this way we are able to protect our oil from air, light, and temperature changes, which represent the main enemies of the oil since they favor the oxidation of nutrients and accelerate their deterioration irreversibly. Each silo contains a unique identification code, through which it is possible to trace the complete path of the olive oil.

6) BOTTLING

Distinguishing features: Cuimani Extra Virgin Olive Oil is bottled in dark-colored containers for a better protection from light, for which we use sustainable and highly recyclable materials such as glass. Bottling takes place in small batches just before the olive oil is picked up by the carrier in order to guarantee a fresh product all year round.

Quality control: Cuimani produces its olive oil under the standards of the Protected Geographical Indication (PGI Sicilia), which is subjected to further quality controls even after bottling. At each bottling our samples are delivered to IRVOS, the body that regulates the PGI Sicilia olive oil production and verifies that the olive oil on the label exactly matches its real content. From the sensorial profile, to the organoleptic properties, to the origin of the product.